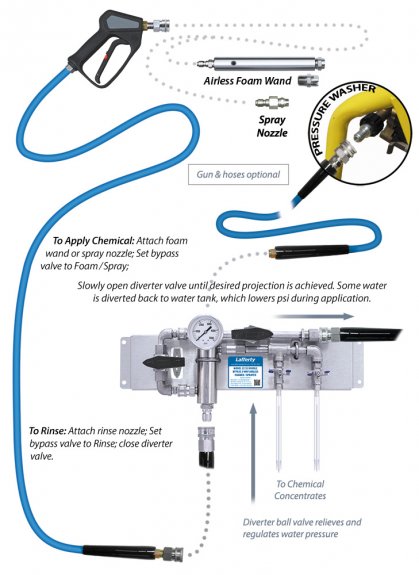

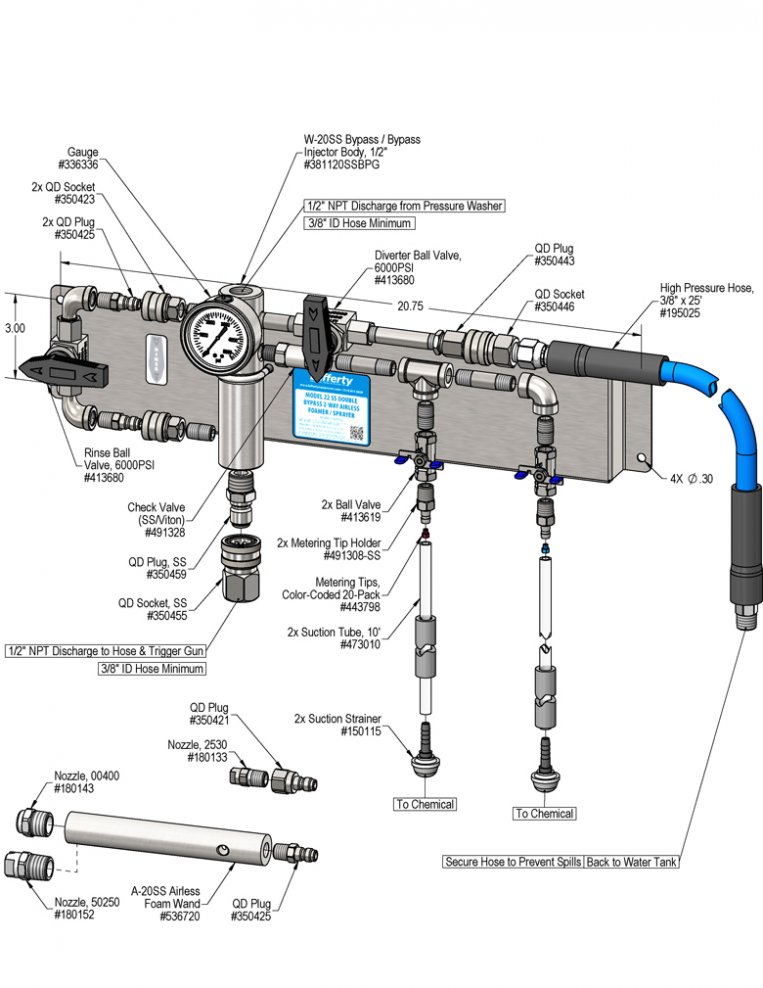

Designed for 5.5–10+ GPM pressure washers. The Model 22 SS Double Bypass 2-Way Airless Foam/Spray System features a diverter ball valve to control pressure, flow and foam throw distance. During chemical application, the diverter valve decreases pressure and flow incrementally the more it is opened, sending water back to the tank so the unit operates at 5 GPM or less. The stainless steel venturi injection system draws and blends two separate chemicals or two different concentrations of the same chemical into the water stream to create an accurately diluted solution. The solution then flows through the hose and gun to the airless foam wand which draws in atmospheric air to create and project wet, clinging foam on to surfaces up close or at distances up to 25 feet with interchangeable fan and zero degree nozzles. Quick connect the fan pattern sprayer nozzle to apply non-foaming chemicals. To rinse at full volume and pressure, close the bypass and diverter valves and switch to a rinse nozzle.