| Chemical Concentrate |

| Water | |

| Temperature | up to 160°F |

| Pressure | 25-125 PSI |

| Supply Line | 1/2" Minimum |

| Flow | |

| High Flow (Black Injector) | 4.0 - 7.3 GPM |

| Low Flow (White Injector) | 1.9 - 3.4 GPM |

| Bottle Fill (Blue Injector) | 0.6 - 1.0 GPM |

Requirements

| Chemical Concentrate |

| Water | |

| Temperature | up to 160°F |

| Pressure | 25-125 PSI |

| Supply Line | 1/2" Minimum |

| Flow | |

| High Flow (Black Injector) | 4.0 - 7.3 GPM |

| Low Flow (White Injector) | 1.9 - 3.4 GPM |

| Bottle Fill (Blue Injector) | 0.6 - 1.0 GPM |

Overview

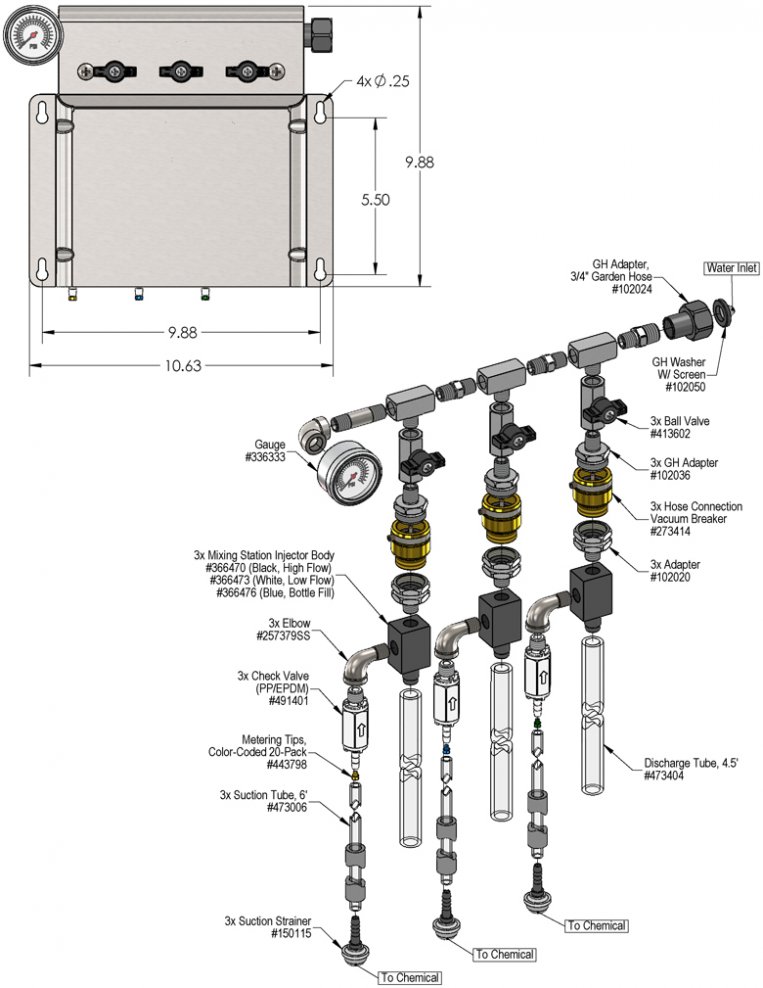

The 3-Way Ball Valve Mixing Station is an ASSE 1055 certified chemical proportioner that accurately dilutes chemicals to the required ratios and dispenses into any size container. This venturi injection system uses city water pressure (25 - 125 PSI) to draw and blend chemical concentrate into the water stream and precision metering tips to set the dilution ratio for each valve. Ball valve activation allows for hands-free dispensing. Choose a factory-set flow rate for each ball valve at the time of order (Bottle Fill, Low Flow, High Flow).

Safety & Operational Precautions

Installation for Devices Plumbed to a Faucet with a Vacuum Breaker

Device certified to meet ASSE Standard 1055 (Chemical Dispensing Systems with Integral Backflow Prevention)

![]()

To Install (refer to diagram on next page)

TO SET DILUTION RATIO, thread a color-coded metering tip into each tip holder. See chemical labels for dilution ratio recommendation or consult your chemical supplier.

If a leaner solution than the maximum shown in the chart is required, it will be necessary to use one proportioner to pre-dilute the concentrate, and a second to dilute the resulting solution to the required final ratio. If this Double Dilution procedure is required, choose two metering tips whose ratios, when multiplied together, result in a ratio that is as close as possible to the required final ratio. Example: For two "Bottle Fill" Mixing Station valves with 40 PSI water pressure, use a White Tip (37:1) and a Corn Yellow Tip (21:1) to achieve a final solution ratio of 777:1.

To Operate

Metering Tip Selection | ||||

|---|---|---|---|---|

Metering Tip Color |

OZ/MIN |

Dilution Ratio | ||

| High Flow | Low Flow | Bottle Fill | ||

Brown | 0.56 | 1031:1 | 480:1 | 142:1 |

Clear | 0.88 | 656:1 | 305:1 | 90:1 |

Bright Purple | 1.38 | 418:1 | 195:1 | 58:1 |

White | 2.15 | 269:1 | 125:1 | 37:1 |

Pink | 2.93 | 197:1 | 92:1 | 27:1 |

Corn Yellow | 3.84 | 150:1 | 70:1 | 21:1 |

Dark Green | 4.88 | 118:1 | 55:1 | 16:1 |

Orange | 5.77 | 100:1 | 47:1 | 14:1 |

Gray | 6.01 | 96:1 | 45:1 | 13:1 |

Light Green | 7.01 | 82:1 | 38:1 | 11:1 |

Med. Green | 8.06 | 72:1 | 33:1 | 10:1 |

Clear Pink | 9.43 | 61:1 | 29:1 | 8:1 |

Yellow Green | 11.50 | 50:1 | 23:1 | 7:1 |

Burgundy | 11.93 | 48:1 | 23:1 | 7:1 |

Pale Pink | 13.87 | 42:1 | 19:1 | 6:1 |

Light Blue | 15.14 | 38:1 | 18:1 | 5:1 |

Dark Purple | 17.88 | 32:1 | 15:1 | 4:1 |

Navy Blue | 25.36 | 23:1 | 11:1 | 3:1 |

Clear Aqua | 28.60 | 20:1 | 9:1 | 3:1 |

Black | 50.00 | 12:1 | 5:1 | — |

| No Tip Ratio Up To: | 4.8:1 | 3.5:1 | 1.7:1 | |

| The dilution ratios above are approximate values. Due to chemical viscosity, actual dilution ratios may vary. | ||||

Formula | ||||

|

GPM × 128 ÷ Desired Dilution Ratio = oz/min

| ||||

Unit Flow Rates | |||

|---|---|---|---|

| PSI | GPM | ||

| High Flow | Low Flow | Bottle Fill | |

| 35 | 4.22 | 1.96 | 0.58 |

| 40 | 4.51 | 2.10 | 0.62 |

| 50 | 5.04 | 2.35 | 0.69 |

| 60 | 5.52 | 2.57 | 0.76 |

| 70 | 5.97 | 2.78 | 0.82 |

| 80 | 6.38 | 2.97 | 0.88 |

| 90 | 6.77 | 3.15 | 0.93 |

| 100 | 7.13 | 3.32 | 0.98 |

| 110 | 7.48 | 3.48 | 1.03 |

| 120 | 7.81 | 3.64 | 1.07 |

| 125 | 7.97 | 3.71 | 1.10 |

Troubleshooting Guide |

|---|

| Problem | Possible Cause / Solution | |

|---|---|---|

| Startup | Maintenance | |

| A) Unit will not draw chemical. B) Dilution too weak. C) Dilution too strong D) Water backing up into chemical container. E) Vacuum breaker constantly dripping / leaking. | 1, 2, 3 4 5 |

6, 7, 8, 9, 10, 11 11 8 12, 13 |

| Possible Cause / Solution | |

|---|---|

| Startup | Maintenance |

|

|

PREVENTIVE MAINTENANCE: When the unit will be out of service for extended periods, place chemical tube(s) in water and flush the chemical out of the unit to help prevent chemical from drying out and causing build-up. Periodically check and clean chemical strainer and replace if missing. |