| Ready-to-Use Chemical Solution | |

| Temperature | up to 120°F |

| Accepts Compressed Air | up to 45 PSI |

Lafferty Equipment Manufacturing, LLC

Installation & Operation Instructions

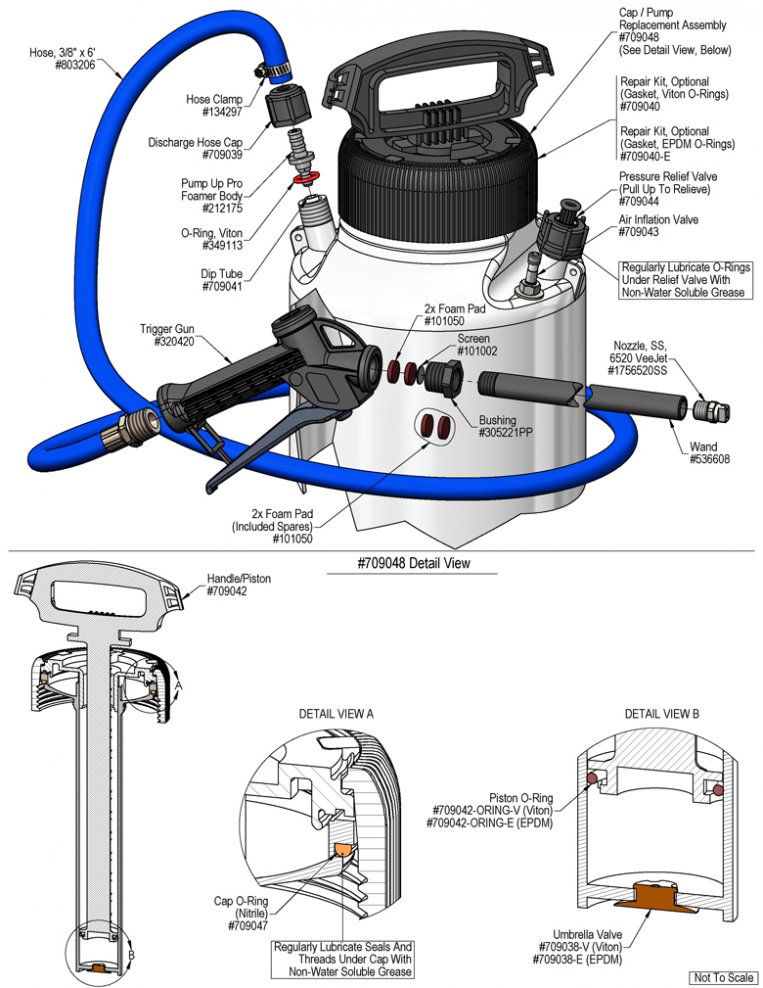

Model # 925005 · Pump Up Foamer Pro, 3 Gallon

Requirements

Overview

The 3 Gallon Pump-Up Foamer Pro is a portable foam applicator for applying foaming chemicals to any surface as high-quality, rich, clinging foam. This professional model projects foam in a wide fan pattern for quick, but still precise, foam coverage. The 3 Gallon Pump-Up Foamer Pro features a heavy-duty hose, trigger gun, and extension wand and combines the many advantages of foam cleaning with the familiar ease and portability of a typical pump-up sprayer. If compressed air is available, use the "quick charge" valve to eliminate pumping!