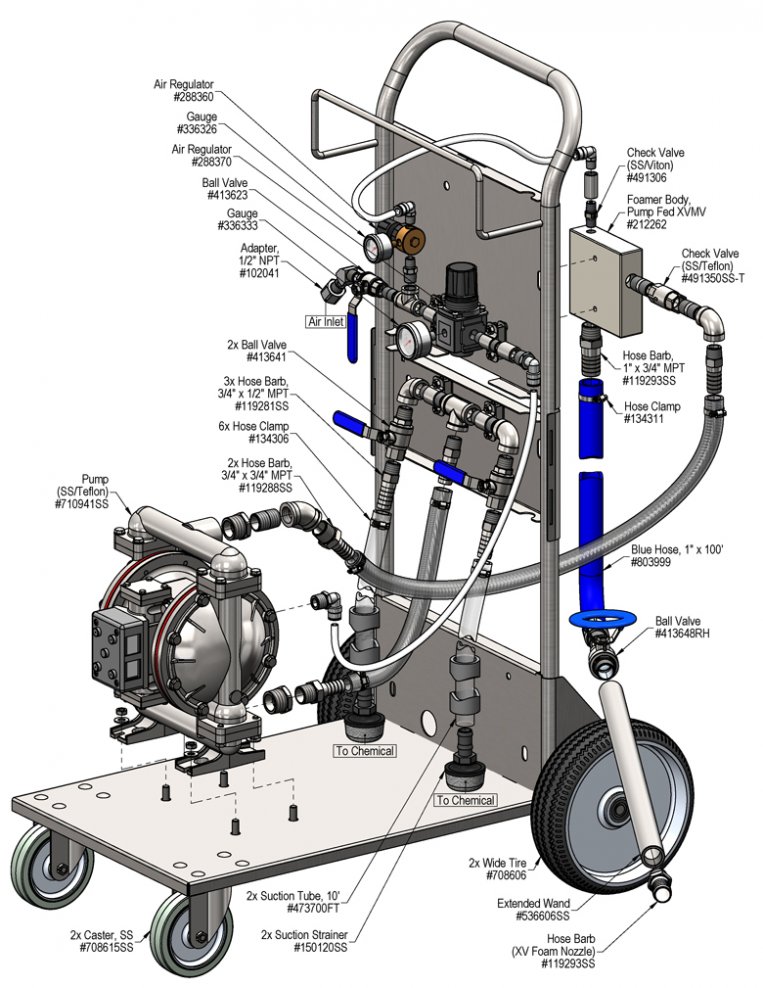

Overview

The Portable SS XVMV Foamer is an extra-high volume foam applicator designed for facilities with low or fluctuating water pressure. Powered completely by compressed air it projects foaming chemicals on to any surface up close or at distances up to 40 feet. A stainless steel 1" air pump, with Teflon diaphragms, is used to draw water and chemical concentrate from static tanks or to draw pre-diluted chemical. Chemical dilution is accomplished by regulating the flow of chemical and water using ball valves. Compressed air is injected into the solution to greatly increase volume and coverage ability. An incredible volume of rich clinging foam is projected through the hose, wand and nozzle.